3-Achieve best carcase dressing

Manage cattle two to three weeks before sale and during mustering and transport to achieve best carcase dressing percentage and avoid downgraded meat and carcases

Guidelines for managing cattle two to three weeks before sale and during mustering and transport

The total price received for your cattle can suffer if the carcase contains dark cutting meat or bruising. This can reduce the total weight of carcase receiving payment due to trimming of bruised meat from those parts not included in the AUS-MEAT bruise scoring areas. The price for the remaining (trimmed) carcase may also be reduced.

Practise good presale management to maximise returns

The causes of dark cutting meat and bruising can be controlled by managing the:

- yard weaning to accustom cattle to human contact in yard situations

- nutrition of animals over the last two to three weeks before sale

- handling of animals immediately before and during transport

- handling and slaughter procedures on arrival at the abattoir.

Finish cattle for market on high quality pasture or feed supplements

The content of glycogen stored within the muscles of the animals at slaughter has a major influence on ultimate pH and eating quality of the meat. Eating quality is affected when there is too little glycogen present.

When glycogen stores are depleted the pH of meat may exceed 5.7 and a darker, unacceptable meat colour develops. Muscle glycogen can be maintained by ensuring cattle keep growing for at least two weeks (preferably four weeks) before slaughter and are not unduly stressed before slaughter. The susceptibility of cattle to stress during handling and transport can also be reduced if they have been accustomed to contact with humans, particularly at weaning as described in Module 5: Weaner throughput and if they are also handled using low stress stock handling techniques (see Module 6: Herd health and welfare)

Manage on-farm factors that influence dressing percentage

The carcase dressing percentage declines rapidly when the nutritional quality of feed declines. Dressing percentage can also be affected by:

- total time off feed before slaughter

- animal’s genetic make-up

- animal’s fat cover and muscle score

- ‘shrinkage’ or trim percentage applied by the processor.

The breed of your cattle is also an important component of maximising the dressing percentage, for example the production of lightly muscled dairy breeds and their crosses is likely to result in lower than average dressing percentages. A working knowledge of the procedures used by the purchaser to assess shrinkage when determining the weight of cattle delivered to an abattoir is also essential if animals are to be managed effectively before slaughter to receive the best price per head.

Use feedback to finetune management of the production system

When available, abattoir feedback will inform you of the corrective actions to be taken to reduce dark cutting and bruising. If problems are identified, you need to consider the following corrective actions.

- Move stock to an appropriate pasture with a nutritional quality of more than 11MJ ME/kg DM and preferably at least 1,500kg green DM/ha, or feed high-energy supplements during the last three weeks before sale.

- Only feed high energy supplements during the last three weeks before sale when it can be managed carefully to avoid nutritional disorders and competition/jostling for feed.

- Sell cattle before pasture quality falls below 11MJ ME/kg DM.

- Avoid stressing animals during droving and transport to the abattoirs.

- Use appropriate ‘cattle moving’ practices (see 'Tips for better cattle handling' box, below).

- Maintain regular contact between humans and cattle throughout their life.

- Avoid mixing mobs of cattle during droving, transport to and at the abattoirs.

- Use polled breeds or ensure horned animals are dehorned appropriately.

- Change yard and transport structures and systems to avoid bruising by ensuring that yards and loading facilities do not have sharp corners or areas where animals can form a crush. Ensure adequate constraint, no sharp edges and correct numbers of animals per compartment during transport.

- Ensure time off feed is most appropriate for the particular market outlet.

If you are not confident that an animal will meet a tight market specification, such as Meat Standards Australia (MSA) (see Tool 7.3), put it into a market with different specifications.

Tips for better cattle handling

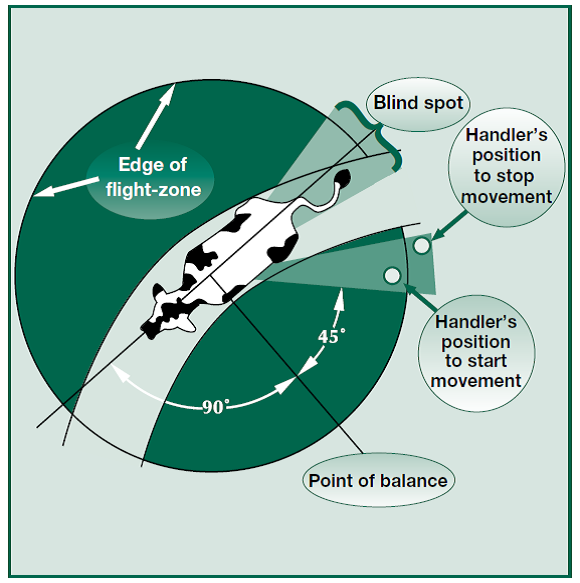

Cattle have wide angle vision in excess of 300°. To move cattle more easily, understand the ‘flight zone’ outlined in Figure 1 and associated behavioural patterns.

- Work with the lead animal; the others will follow.

- Position yourself adjacent to the head of the lead animal and at about 90° to the direction the mob is to be moved.

- Be at a distance appropriate for the particular mob (ie where your presence is recognised but the lead animal does not attempt to move away from you).

- Be on the side of the lead animal that you wish the mob to turn away from (cattle are uncomfortable losing eye contact with you and are reluctant to turn with their back towards you).

- Moving forward 90° will cause the lead animal to slow down, and moving behind 90° will either speed the animal or encourage it to turn towards you.

Figure 1: The flight zone surrounding cattle

What to measure and when

- Use Meat Standards Australia (MSA) guidelines as standard operating procedure.

- Measure pasture quality and availability over the three weeks immediately before sale.

- Check compliance reports from the abattoir on carcase downgrades due to high ultimate pH, dark cutting meat and bruising. The location of bruising may indicate the possible cause so that appropriate action can be taken.

- Monitor the time cattle are off feed in relation to the target market.

- Weigh and assess cattle for fatness, then draft into sale mobs, preferably two to three weeks before sale to minimise stress and bruising.

Further information

- NSW Department of Primary Industries Agnote series on dark cutting (2001)

- MLA has produced a range of publications to assist producers understand and meet MSA specifications.

- NSW Department of Primary Industries Primefacts no. 340 (2007), Dressing percentages for cattle.